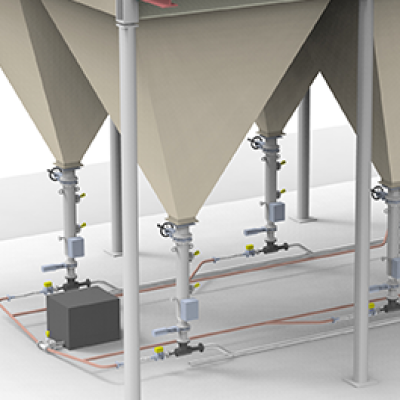

Our Catalyst Loaders are designed and developed to be easily installed below existing storage hoppers. Our base model loader is able to load the Catalyst and Additive through the loader into the regenerator.

We offer 2 sizes of this loader with maximum addition of 30 MT/day.

Operation is VERY simple. Just give in the required daily addition rate and kg per shot and the computer will do the rest. Common plant problems such as pressure failure , blocked FCC lines and filling line problems are included in the software and will be self-adjusted as much as possible. Accuracy 99.9%

The skid is delivered completely assembled and is tested for 48 hours before it will leave our shop.

The only connection to be made on site are:

• Filling line to the storage hopper

• Discharge line FCC

• Main air connections

• Main power supply (to main switch)

• Exhaust line connection

What can we offer you?

• Reliability

• Convenience

• Compact skid

• Minimum maintenance

• Easy operation

• Efficient back up service