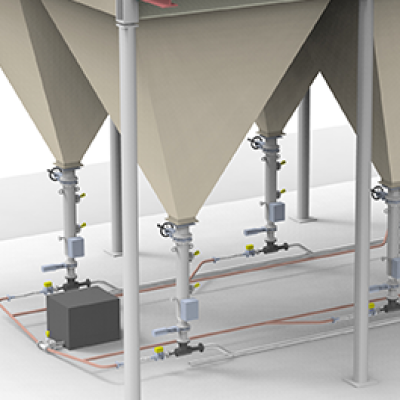

Our Additive Loaders are designed and developed to easily transfer the Catalyst or Additive through the loader into the regenerator. The available Storage Hopper is part of the scope of supply!

We offer a few different capacities of storage hoppers and the system is designed for maximum addition of 3 MT/day.

When additives are supplied in drums/flowbins or big bags they can be loaded into the storage hopper with the vacuum producer available on top of the storage hopper.

Operation is VERY simple. Open the vacuum producer valve (air driven) and put the pick-up tool into the drum or big bag. After the hopper is full, the additives can flow by gravity into the pressure vessel. The A model loader has proven itself to be extremely reliable for over 30 years in operation.

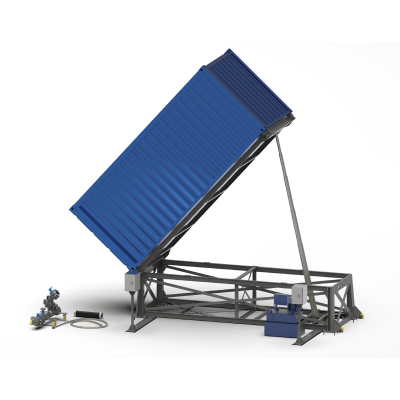

The skid is delivered completely assembled and is tested for 48 hours before it will leave our shop.

The only connections to be made on site are:

• Install the storage hopper on top of the base unit

• Discharge line FCC

• Main air connections

• Main power supply (to main switch)