Our Multi Ingredient Loaders are designed and developed to meet the requirements of refineries nowadays. Our base model loader is upgraded in such a way that it can add up to 4 products in only one loader.

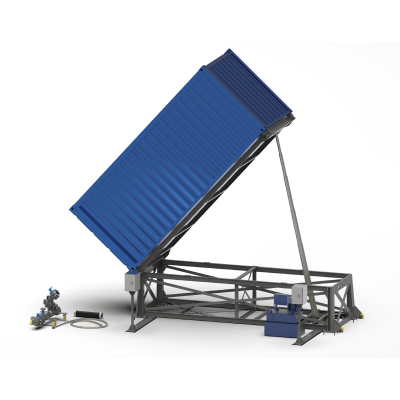

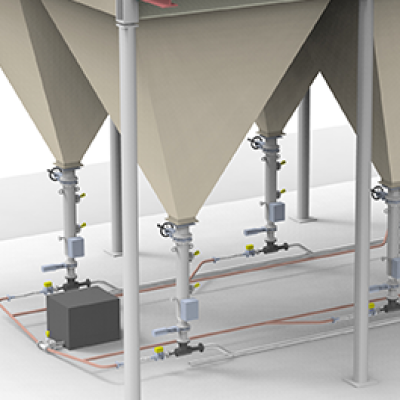

The Quattro 2.0 loaders are ideal to install in situations where additives are supplied in various ways such as, drums, big bags or tote (flow) bins. The main base loader should be used for the catalyst feed and up to 3 different additives can be blended additionally. This model is also a modular set up. Over the base unit, a top frame will be erected which consist of the following:

• Vacuum type storage hoppers (2m3)

• Vacuum producer (air driven)

• Automatically cleaned vacuum / exhaust filter

• Galvanized frame with caged ladder and safety railings.

• All necessary valves for simply filling of the hoppers

• Optional – level indication on the hoppers

Of course, all necessary safety features that are required for use on refinery plant have been taken into account.

Operation is VERY simple. Just give in the required daily addition rate and kg per shot for the

catalyst. Then enter the daily rate for each additive (connected) . The computer will calculate the injections and make sure the catalyst and additive is evenly injected during 24 hours.

When an additive hopper is empty a warning is given, but the loader will continue with the other ingredients. The display of the terminal shows what ingredient is empty.

Common plant problems such as pressure failure , blocked FCC lines and filling line problems are included in the software and will be self-adjusted as much as possible.

The skid is delivered completely assembled and is tested for 48 hours before it will leave our shop.

The only connections to be made on site are:

• Install the storage hopper on top of the base unit

• Discharge line FCC

• Main air connections

• Main power supply (to main switch)